Licensed Welding Inspection Service for Building Sites

Licensed Welding Inspection Service for Building Sites

Blog Article

Enhance Your Projects With Specialized Welding Services: Kinds and Advantages

In the globe of building and construction and manufacturing, the importance of specialized welding solutions can not be overemphasized. From complex tasks that require accuracy to massive industrial applications, the appropriate welding method can make a significant difference in the outcome of a job. As developments in technology remain to shape the welding sector, comprehending the kinds of specialized welding solutions offered and the advantages they offer is critical for remaining in advance in an open market. Whether it's the effect on building jobs, the applications in the manufacturing sector, or the benefits for numerous industries, checking out the realm of specialized welding solutions unveils a globe of opportunities that can raise tasks to new heights.

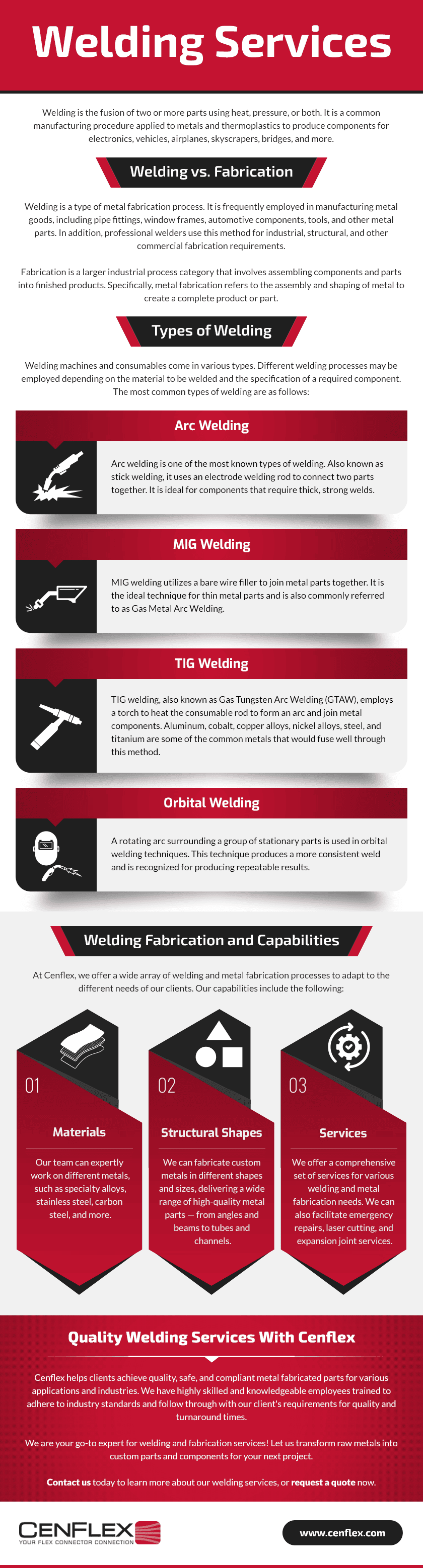

Types of Specialized Welding Solutions

Specialized welding solutions incorporate a range of strategies tailored to certain industrial applications, consisting of however not restricted to TIG welding, MIG welding, and immersed arc welding. Tungsten Inert Gas (TIG) welding, known for its accuracy and clean welds, is typically utilized in markets calling for high-quality welds on products like stainless steel and light weight aluminum.

Each of these specialized welding methods uses distinct advantages customized to certain task needs, highlighting the relevance of choosing the proper technique based upon material, density, and preferred weld qualities.

Benefits of Specialized Welding Solutions

The advantages of utilizing specialized welding solutions in commercial applications are manifold, varying from improved accuracy to enhanced efficiency in taking care of specific products and project requirements. One considerable benefit of specialized welding services is the proficiency and experience that welders bring to the table. These experts are educated in different specialized welding methods, making sure that the welding procedure is executed with the highest possible level of ability and accuracy.

Influence On Construction Jobs

Attracting on the competence of specialized welding solutions in industrial applications, the influence on construction jobs is substantial in terms of precision, effectiveness, and total quality of welds. Building tasks rely heavily on the architectural stability of welded components, making the accuracy used by specialized welding critical. By using specialized welding services, building and construction groups can ensure that each weld satisfies the required specs, reducing the threat of structural failures.

Furthermore, specialized welding techniques improve effectiveness in building and construction jobs by simplifying the welding procedure. With specialized devices and trained professionals, tasks that would certainly otherwise be lengthy can be completed faster without endangering quality. This effectiveness not just accelerates project timelines but likewise lessens labor prices linked with welding.

Furthermore, the general high quality of welds in building jobs is considerably boosted via specialized welding solutions. These services frequently involve advanced welding technologies and extremely proficient welders who can create more powerful, extra durable welds. The premium quality of welds accomplished through specialized services adds to the durability and reliability of construction tasks, making sure that frameworks stay protected for years to come.

Applications in Manufacturing Industry

Within the manufacturing industry, the usage of specialized welding services plays a crucial duty in guaranteeing the integrity and performance of production processes. Welding is a basic process in manufacturing, made use of in different applications such as joining metal components, producing structures, and fixing tools. Specialized welding strategies like TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and robotic welding are extensively employed to fulfill the industry's certain demands.

One significant application of specialized welding in production remains in the automobile sector. Welding is critical in the setting up of automobile components, making certain structural security and security. In addition, the aerospace market greatly depends on specialized welding services to fabricate airplane parts with high precision and toughness to hold up against severe conditions.

In addition, in the manufacturing of equipment and devices, specialized welding plays a crucial role in producing trustworthy and resilient items. By utilizing sophisticated welding approaches, producers can improve item high quality, boost production effectiveness, and eventually supply remarkable items to the market - Welding Inspection Service. The accurate and elaborate nature of specialized welding services makes them important in the production sector's quest for advancement and quality

Benefits for Various Industries

With the pivotal function that specialized welding solutions play in the production industry, it is evident that their advantages extend read what he said across various industries, supplying important benefits for various sectors. One significant advantage is raised performance. Specialized welding strategies permit faster manufacturing processes, lowering downtime and boosting total efficiency in industries such as automotive manufacturing, aerospace, and building. Furthermore, specialized welding services offer boosted precision and quality control, making certain that the end product satisfies stringent industry standards. This precision is specifically vital in industries such as electronic devices producing and medical tools manufacturing, where even small flaws can have serious effects. Furthermore, specialized you can try here welding services can aid sectors satisfy details regulative requirements, such as those in the oil and gas industry or the nuclear sector, where security and integrity are critical. By leveraging specialized welding services, numerous markets can boost their operations, improve product top quality, and ultimately achieve better success in today's affordable market.

Verdict

In final thought, specialized welding solutions offer a range of benefits for building tasks and the manufacturing industry. With different kinds of welding solutions offered, such as robot welding and laser welding, businesses can enhance the quality and effectiveness of their tasks. The effect of specialized welding solutions prolongs throughout several markets, giving benefits in terms of cost-effectiveness, precision, and toughness. Embracing specialized welding services can cause boosted task outcomes and boosted competition in the marketplace.

As developments in technology proceed to shape the welding sector, recognizing the kinds of specialized welding services available and the benefits they offer is important for staying ahead in an affordable market.Specialized welding services encompass an array of techniques customized to details industrial applications, consisting of however not limited to TIG welding, MIG welding, and immersed arc welding.Furthermore, specialized welding services often make use of sophisticated equipment and technologies that are particularly designed for Resources intricate welding projects. Specialized welding methods like TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and robot welding are extensively used to satisfy the industry's certain requirements.

Report this page